> Business > Technology

> Business > Technology

|

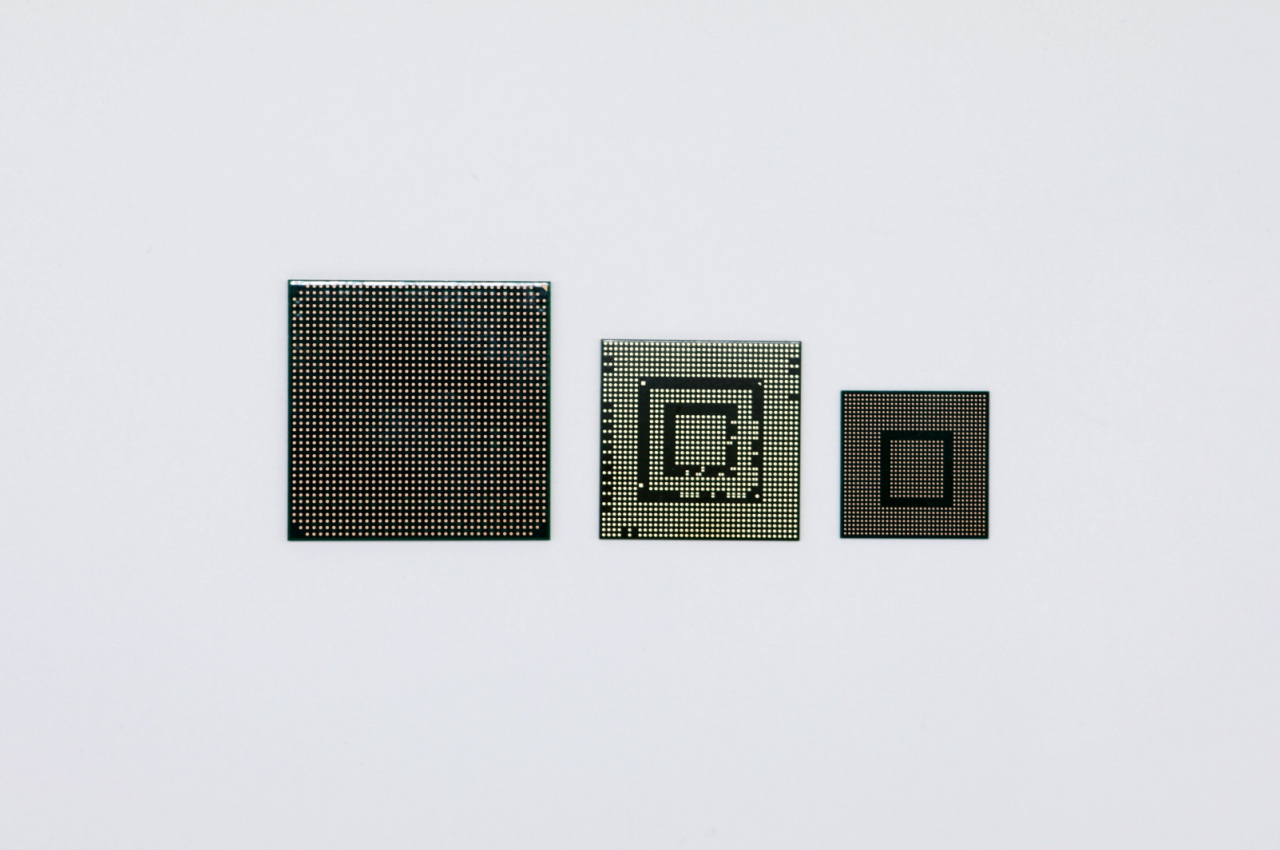

| An image of flip chip ball grid array products that applied LG Innotek's raw material incoming inspection artificial intelligence (LG Innotek) |

LG Innotek said Wednesday that it has developed the industry’s first artificial intelligence that detects defective raw materials for its chip substrates.

The new system, combining AI-based material information and image processing technologies, has already been adopted for the company’s production process. More recently, it has been used to upgrade the product quality of value-added chip substrates, including the flip-chip ball grid array.

With chip substrates becoming increasingly sophisticated, the company said, it has become crucial to guarantee materials quality but conventional visual inspections have often failed to detect defects.

The new AI can inspect materials quality with more than 90 percent accuracy in just one minute, according to the company.

“With the introduction of this material inspection AI, we can identify various defect causes in products in advance and provide differentiated customer value. We have now completed LG Innotek's unique AI ecosystem,” said Chief Technology Officer Roh Sung-won. “We will continue to innovate digital production to deliver the highest quality products at the lowest costs in the shortest time possible."

LG Innotek plans to expand the application of the AI system to optical solutions, including camera modules, which can detect defects based on images.